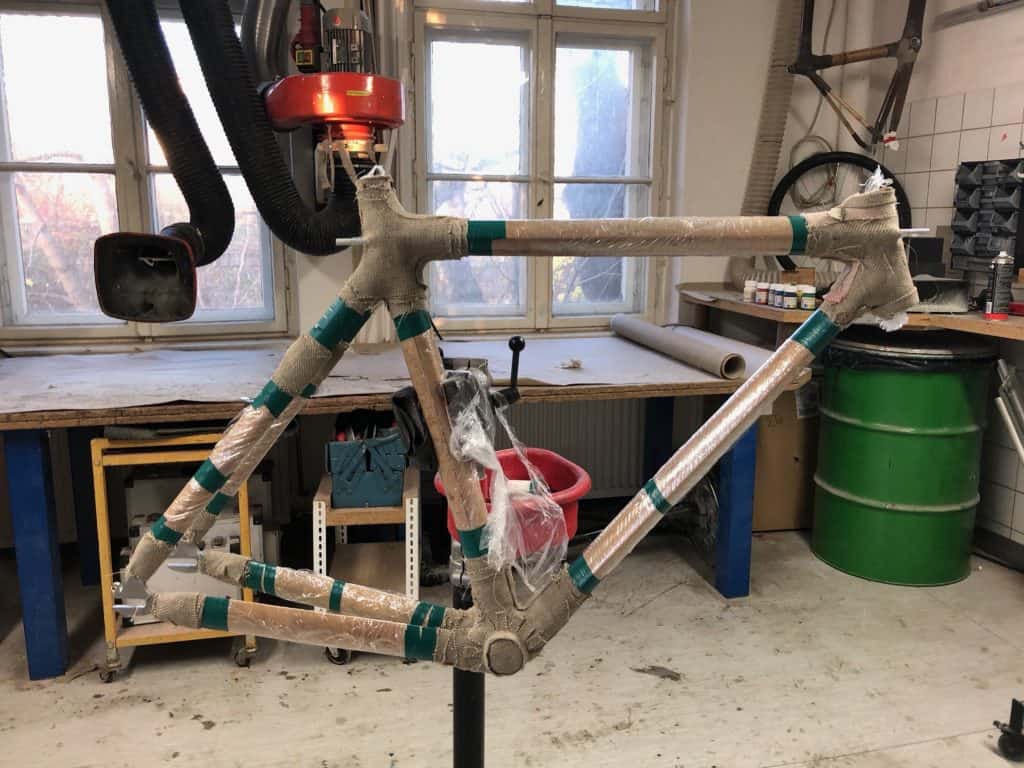

Today is Day #4 and my bamboo bike gets dressed 🥳!

All joints that have previously been spackled, rasped and sanded are Not covered with 3 lagers of flax cloth and afterwards drowned in rather liquid epoxy rasin. So watch out what you’re wearing. Your clothes and shoes will definitely look different on the end of the day than they looked in the beginning. This day you’ll leave your workshop in a mess, if you want it or not.

All you need for the first step are sharp scissors, mesuring tape, a sharpie and adhersive spray. The Second step will require epoxy resin, a cup, a brush colouring pigments, TP, cling film and old bike tubes. you can geht them in your local bike reparier store. They usually keep them and send them back to the wholesaler or manufacturer, so they are happy to Hand them over to you.

Flax fibre is ideal for this purpose. Its a nightmare to cut, but it soaks up the epoxy resin and will in the end become an ideal composite construction material that keeps the bamboo bike frame together for ages. Not only bicycles, but sailing yachts are built. You can really trust this material. It’s durable, water proof and rigid. And it’s a natural fibre. And it absorbs dynamic shocks better than fibre glass and is for this reason longer lasting.

The flax fibre cloth get’s glued to the frame in 3 layers. The glue’s only job is to fixate the cloth to the frame. Don’t use too much glue as it will seal the cloth pores if you use too much and the cloth needs to soak in as much epoxy resin as possible. The first layer is the biggest, all layers shall “shrink” about 1/2-1 inch (1-2cm) from layer to layer.

Put an extra layer on the seams. Don’t let anything out, you really need to do a good job here. It’s not too hard to do, but you need tot do this with some diligence.

OK, I have made up my mind, the joints are count to be black. This might not be the happiest colour in the world, but if you want to get experimental with the color, I would suggest to buy a funky saddle, cranks or shiny breaks. Black joints can easily be combined with any other colour. Epoxy itself has no colour. In general, you can add any colour to your frame at this point. Nor no color at all and give everyone a good view of the raw flax fibre. Or add some sawdust do the epoxy to give your joints a wooden look. Go crazy! Get creative! Don’t listen to me with my sad blackness. But keep in mind that not every color is 100% opaque

The floor is covered with paper, the parts that aren’t getting epoxied are covered with cling film and the ends of the joints are marked with sticky tape. All Joints will get soaked in about 1-2 cups of epoxy. Be generous with your epoxy. Excessive resin will be pressed out of the fabric afterwards. So you can’t put too much on it, only too few.

Now all Excess epoxy will gut pressed out of your bamboo bike frame.

To do this you need to cover the joints in cling film and punch hole with a needle into the cling film. This gets the wrapped up in TP or paper towels . I have used TP as it works perfectly and is cheaper that paper towels. The Tp soaks up all the excessive epoxy. To press the epoxy out, the joints are now wrapped up with your old bike tubes. Wrap them around as tight as possible and all epoxy get’s squeezed out. This really works out fine. Through this compression a very durable composite material will evolve.

day 4 1/2

After about 2 days the epoxy is hardened enough that it’s easy to peel the cling film/ TP/ bike tubes off the joints. Undress your bike now. If you make it easier, the quality won’t be as good, if you do it later, it gets more difficult to peel it all off the frame.